Product Description

1. Chemical composition

The main alloy component of ER1100 aluminum welding wire is

aluminum, which has a high purity, usually containing 99.00% or

more aluminum, and also contains a small amount of impurity

elements such as silicon and iron, of which the silicon content

generally does not exceed 0.9% and the iron content does not exceed

0.7%. This composition characteristic makes it have good corrosion

resistance and conductivity.

2. Mechanical properties

Tensile strength: The tensile strength of the joint after welding of ER1100 aluminum

welding wire is generally around 110MPa - 130MPa, and the specific

value will be affected by factors such as welding process

parameters and parent materials.

Elongation: The elongation of its welded joint can usually reach 20% - 30%,

with good plasticity, and can withstand a certain degree of

deformation without breaking.

3. Welding characteristics

Strong versatility: Suitable for welding 1000 series pure aluminum, such as 1060, 1050

and other grades of aluminum alloys, and is more suitable for

welding some aluminum products with low requirements.

Good operating performance: During the welding process, the arc is stable, the molten droplet

transition is uniform, the spatter is small, and the weld formation

can be well controlled.

Good corrosion resistance: Due to its high-purity aluminum composition, the weld after

welding has good atmospheric corrosion resistance and can meet the

use requirements in general environments.

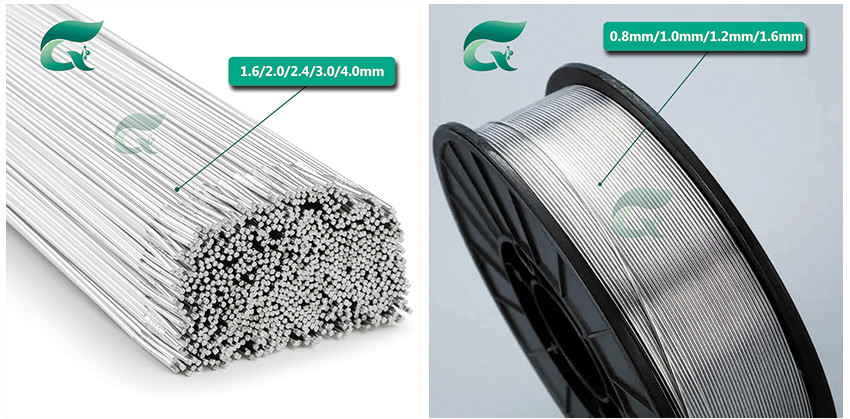

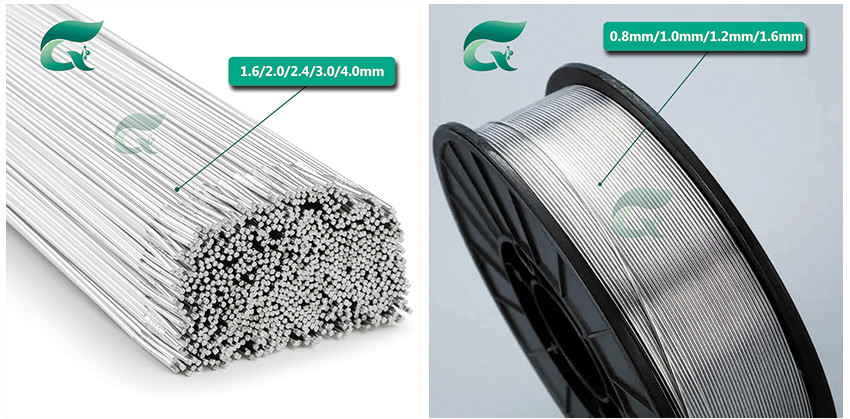

Details Images

| GB/T 10858-2008 SAI 1100 AWS A5.10 ER1100 |

| |

| 1.6mm/2.0mm/2.4mm/3.0mm/4.0mm |

Specifications