Product Description

ER5356 is a commonly used aluminum-magnesium alloy welding wire.

Mechanical properties

Aluminum alloy joints welded with ER5356 welding wire have high

strength and good toughness. Its tensile strength is generally

around 260MPa - 300MPa, its yield strength is about 110MPa -

130MPa, and its elongation can usually reach 20% - 25%.

These mechanical properties make it suitable for many aluminum

alloy structural welding that have certain requirements for

strength and toughness.

Welding characteristics

Good crack resistance: Due to the characteristics of its alloy composition, ER5356

welding wire has good thermal crack resistance during welding,

which can reduce the generation of welding cracks, and is

especially suitable for welding some aluminum alloy materials that

are prone to cracks.

Strong corrosion resistance: The weld after welding has excellent corrosion resistance,

especially for corrosion in seawater, atmosphere and other

environments, so it is often used in shipbuilding, marine

engineering and other fields.

Good welding processability: The welding wire has stable arc, uniform droplet transition, small

spatter and beautiful weld formation during welding. At the same

time, it has strong adaptability to welding parameters, is easy to

operate, and can be used in a variety of welding methods, such as

tungsten inert gas welding (TIG), metal inert gas welding (MIG),

etc.

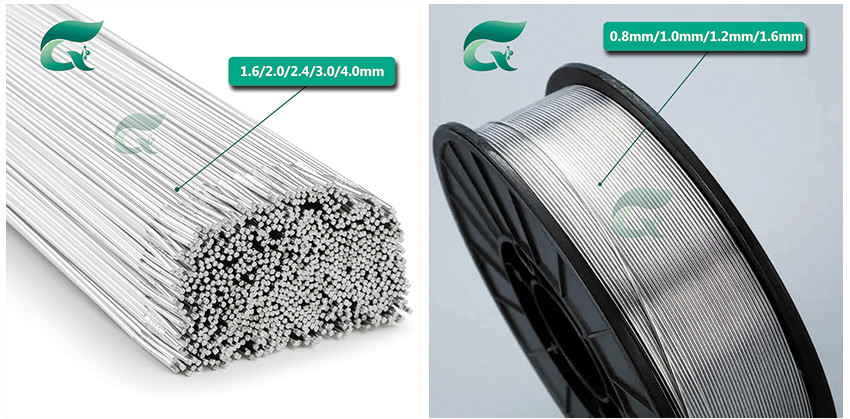

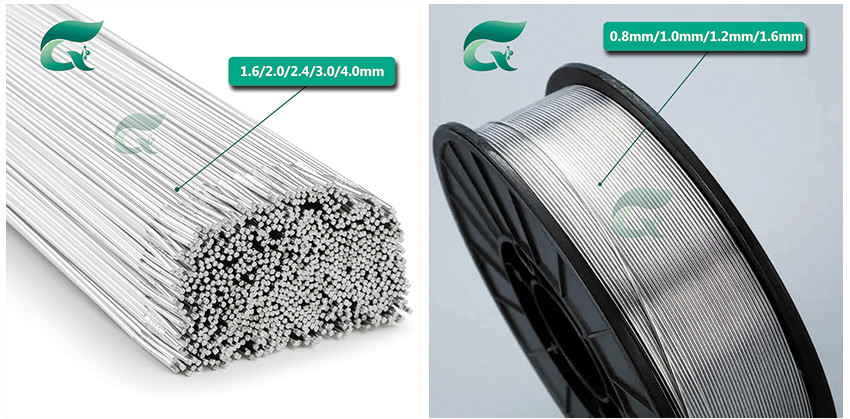

Details Images

| GB/T 10858-2008 SAI 5356 AWS A5.10 ER5356 |

| |

| 1.6mm/2.0mm/2.4mm/3.0mm/4.0mm |

Specifications